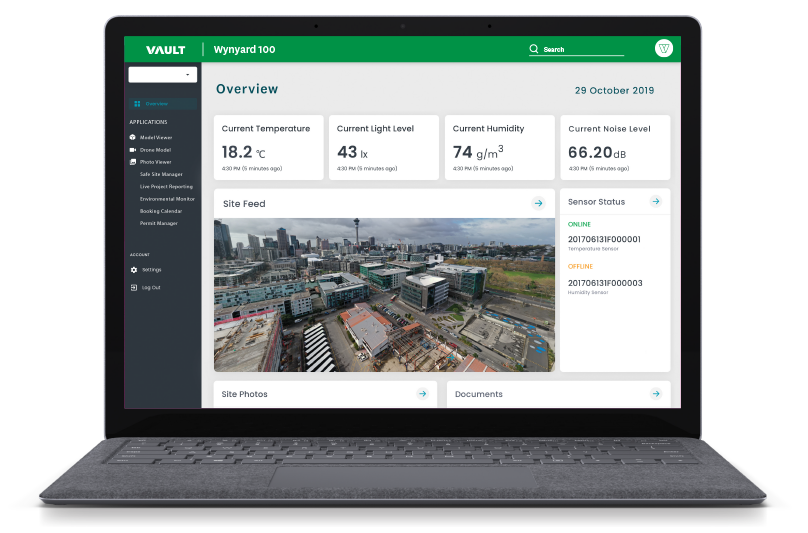

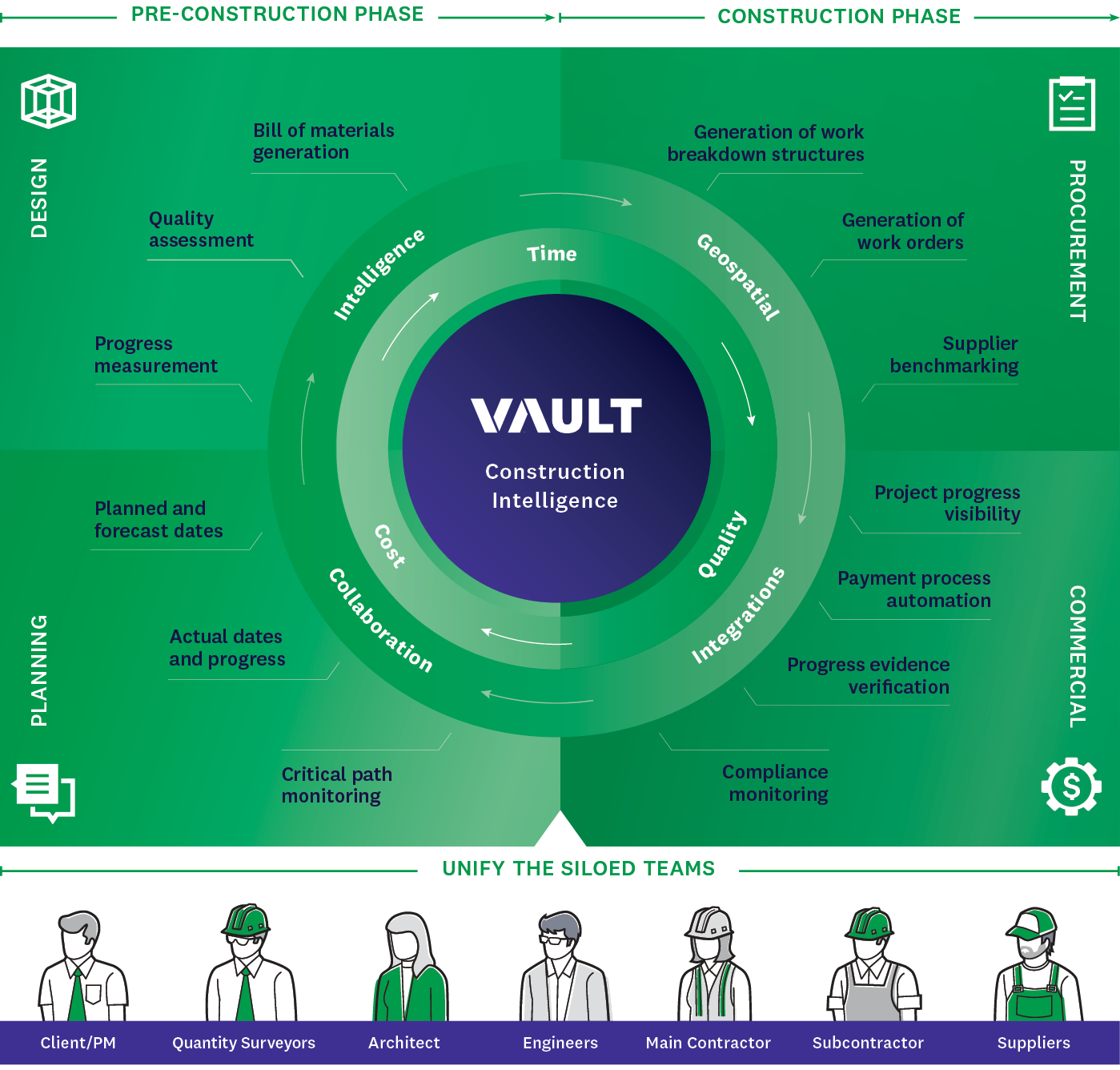

Construction intelligence for the whole project lifecycle

Connect the whole supply chain. Reduce risk, errors, inefficiency and waste. Get powerful real time visibility. Powered by Vault’s 3D spatial intelligence.

From preconstruction to handover, Vault unifies data from traditionally fragmented sources.

- Help construction teams shift from ‘silo to flow’ on a digital foundation

- Vault is built to ingest operational system data from disconnected teams, validating it and combining it

- A proprietary data unification algorithm with a comprehensive business logic layer provides a single viewpoint of project progress

- An easy-to-use interface then delivers targeted functionality for various construction stakeholder groups

- Foster productivity and achieve efficiencies by providing your supply chain visibility across; time, quality and cost elements of the construction process.

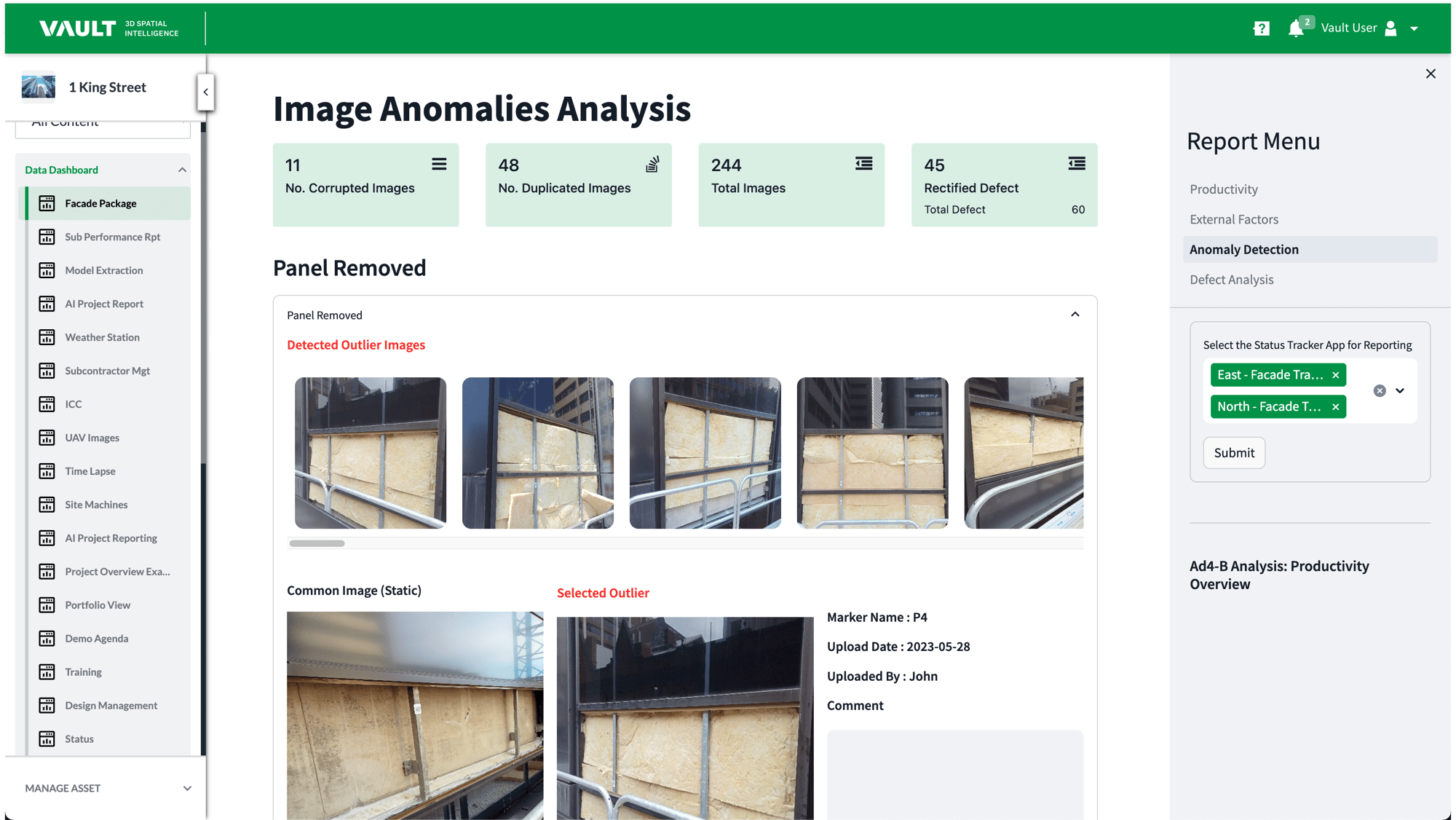

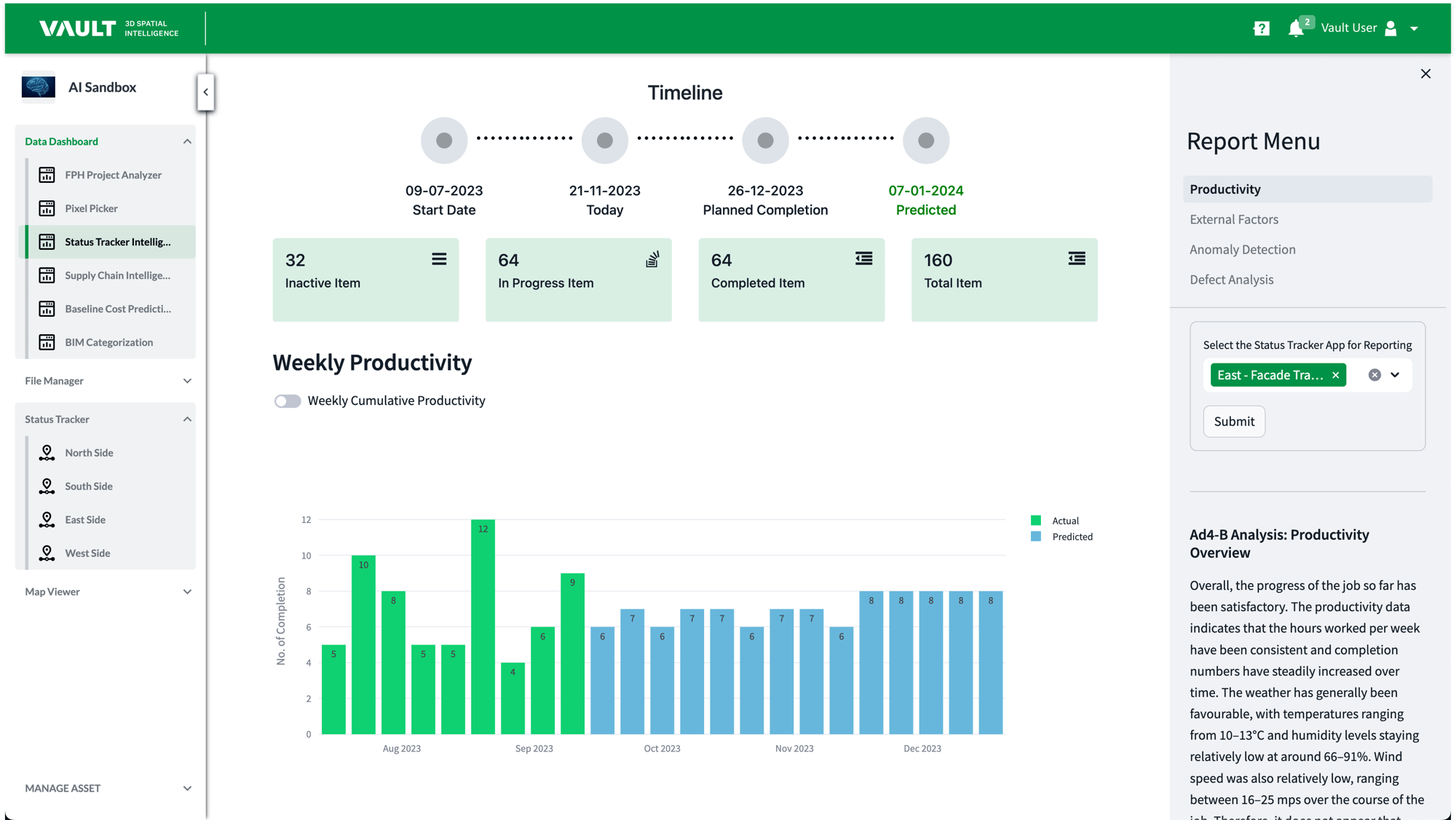

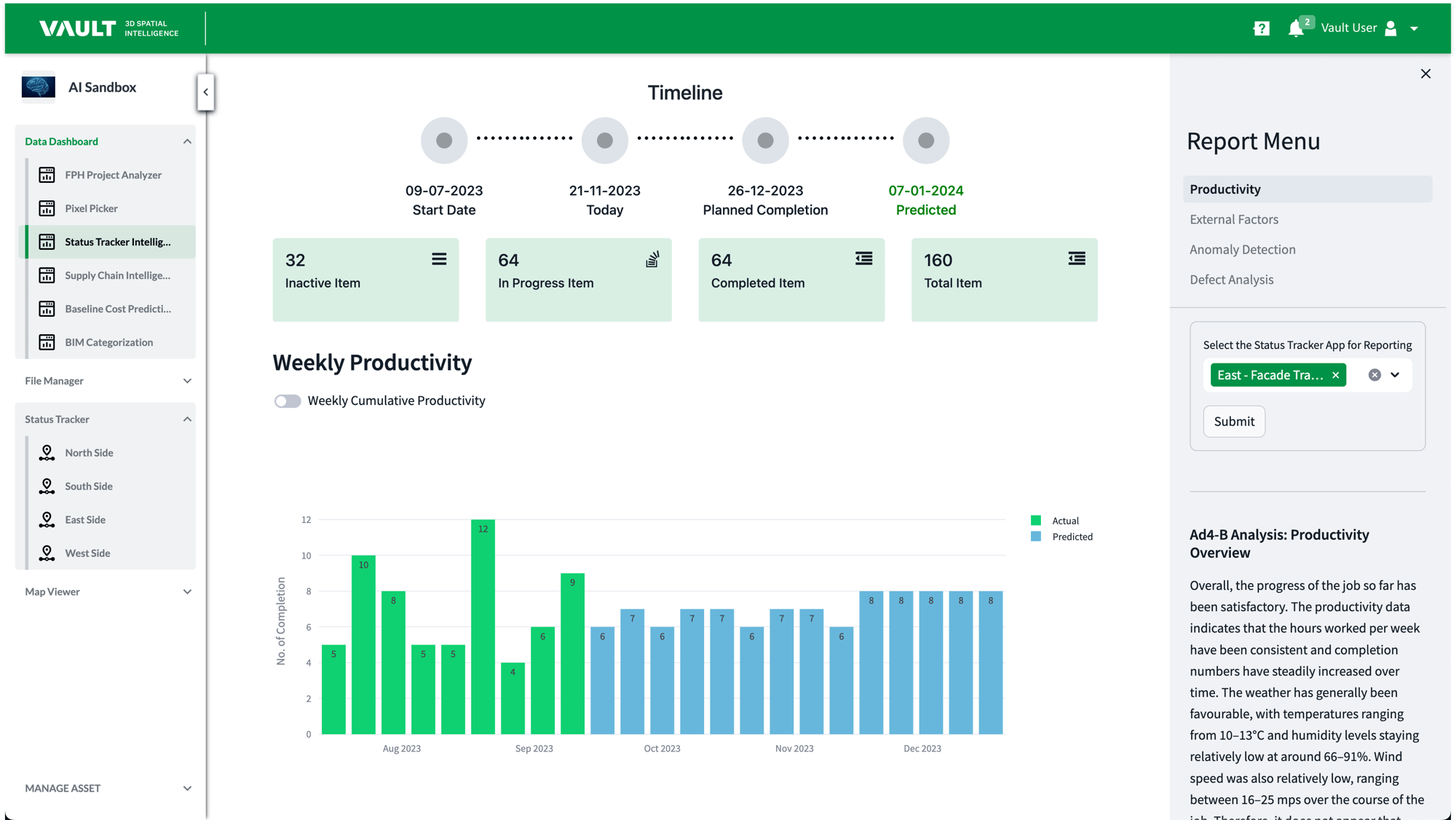

Harnessing AI

Create the foundation for AI and ML and access insights proactively. Vault’s in-built customisable AI framework is used to spot trends and de-risk projects. Generate more advanced, predictive insights, making information more accessible and harness AI to drive actionable insights.

VISUALISED, VERIFIED CONSTRUCTION PROGRESS

Through Vault + PayLab

- Access a single touchpoint of spatially visualised, verified progress - accessible to all.

- Make it easier and faster to present progress, payment and compliance evidence and share information to teams and clients.

- Enable comprehensive verified, visual progress information

- Provide different views of progress and payment data to different user groups

- Create a clear understanding of construction capital requirements – including variation management.

CONSTRUCTION INTELLIGENCE AND PAYMENT DATA UNITY

- Immutable audit trails for payment and variation management

- Excel ingestion engine for subcontractor onboarding

- Computer vision for evidence validation

CONSTRUCTION INTELLIGENCE

WITH PROACTIVE INSIGHTS

Through Vault + AI

- In procurement Vault AI will provide data informed decisions, streamline procurement processes and strengthen supplier relationships by offering insights into vendor performance and reliability.

- In commercial Vault AI will deliver real time productivity and trend analysis. Leverage data-driven insights to optimise budget planning, benchmark analysis, reduce estimation error and enhance financial forecasts.

- In delivery Vault AI will maximise delivery efficiency with real time tracking allowing site teams to identify potential delays or bottlenecks and suggesting corrective actions.

A Smarter Future – today

The construction industry remains one of the least digitised industries, with poor productivity, a heavy environmental footprint and a poor safety record. A lot of time onsite is wasted waiting for equipment to arrive, working out exactly where something should be installed, interpreting printed plans and documents and fixing miscommunications. Time is money. Vault provides the foundation for a future in which:

-

The construction process is digitised

-

Data is united

-

Risk is reduced

-

Productivity is elevated

-

AI is central to everything

-

Waste and carbon footprint is significantly reduced

-

Construction is far safer and industry stress is minimised.