Viewed in real-time via dashboards, a Connected Manufacturing plant will help you predict when things might break down, or where tiny inefficiencies are slowing down your whole factory.

By creating your plant as a digital twin, asBuilt can attach IoT sensors to any and every element to help you interrogate what’s really going on. Monitor inputs, throughputs and outputs spatially and in real-time. And access it all remotely!

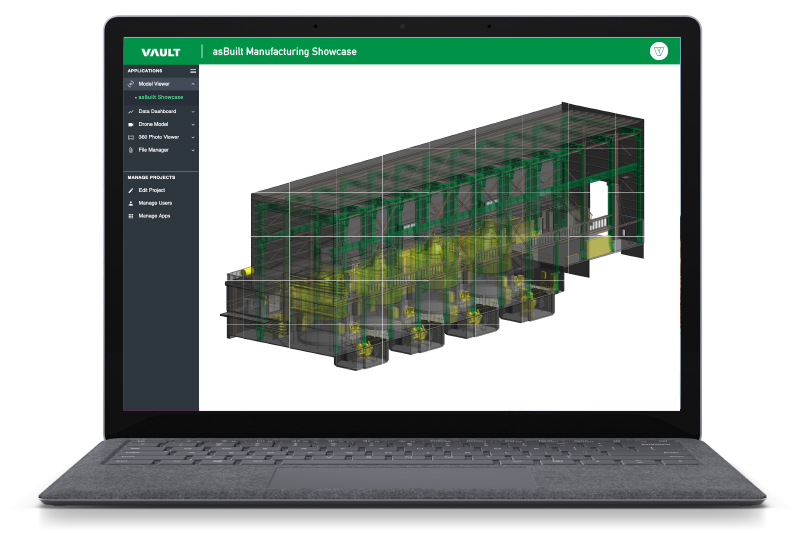

Manufacturing delivered smarter with a Digital Twin

Vault does more than just create a digital version of your manufacturing line. Vault helps you analyse, understand and optimise everything. Live.

Your Smart Plant

Imagine creating a predictive, self-diagnosing manufacturing plant. Gain live actionable insights into the efficiency, speed and bottom-line performance of your organisation, spatially.

Connected Manufacturing

Our Vault 3D Spatial Intelligence platform harnesses the power of IoT connectivity to create a digital twin of your most valuable asset.

VAULT

- Provides live insights

- Connects all elements of your manufacturing plant to one digital source of data truth

- Provides a platform for next generation intelligent technologies

- Reduces operational expenses

- Creates a permanent reference of all manufacturing data captured

The Future of Connected Manufacturing

As IoT connectivity becomes more sophisticated, the potential ways and means to improve your entire operation before, during and after production is almost limitless…

- Establish clear ROI on plant investments in real time

- Interrogate the efficiencies of your manufacturing line like never before to understand why some elements perform better than others

- Optimise disaster management and recovery including simulations on a digital twin

- Drive optimal line efficiencies including likelihood of failure alerts

- Establish comparative performance measures and benchmarks to understand which line is working better and why

- Use pattern recognition features to establish outcome predictability

- Include the wider building infrastructure to understand effects of temperature, moisture, CO2, airflow and more on your manufacturing lines

- Drive incremental improvements on all elements of your manufacturing plant

The first step to increased revenue starts with asBuilt and digitisation...

See how Vault can transform your manufacturing

Request a demo